269.415.0040

269.415.0040

Status quo calls for upgrading the fuel pump to make more power. Seems like an easy way to to make more horsepower because "bigger" seem better. Well the truth is the fuel pumps are the same, the only thing changing is the fuel pressure which in the most honest sense of what is going on, its a band-aid.

Increasing fuel pressure to make injectors flow more is common. My Mitsubishi Evolution 8 drag car for example runs 75psi of base fuel pressure with a 1:1 rising rate regulator to boost pressure, as well at 8x2000cc injectors. Essentially this means with boost pushing on the injectors outlet, and fuel pressure pushing on the inlet, my differential fuel pressure will theoretically always be 75psi. That is not the case with the Can-am. It is a static fuel pressure. As boost rises the differential fuel pressure is dropping. So our injectors on a 2017 Can-am and stock pump have 58psi of fuel pressure and at 18psi of boost, would actually have 40psi of pressure available to push through the injector into the port. The 2018 Can-am has 65psi so just add 7 psi of fuel pressure to the previous statement.

What this all means and why its a band-aid is we really only gain about 30cc per cylinder of fuel flow. Compared to the calculated size of the stock injectors at 470cc, we now have roughly 500cc injectors. Going back to my drag car, 2000cc injectors rated at 43.5psi fuel pressure flow close to 2700cc of fuel at 75psi. 700cc more per injector and I have 2 per cylinder. See why it makes sense to do it with very big injectors and not so much with what we would call small injectors.

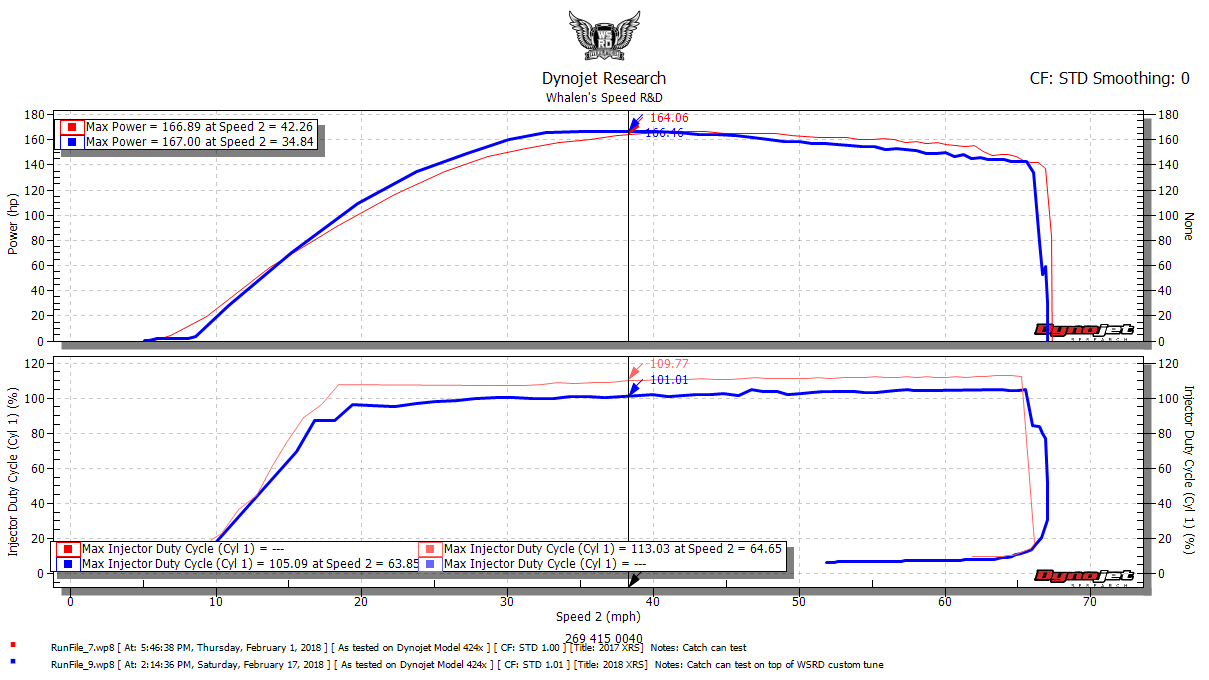

The hard truth, as you can see in the picture in the post, is injector duty cycle is 100% or more, means the injector is always on/no time to shut and rest, at 170ish wheel horsepower. The variables that can occur with an engine with conditions changing may require more fuel if the air is really cold or less fuel if the air is really hot. Pushing this setup any harder in not safe.

Here is a dyno plot of a stock injector 2017(red), stock injector 2018(blue), and a 2017 equipped with our 850cc injector kit(green). As you can see we have significantly dropped injector duty cycle to a much safer area. Its well agreed among tuners for safe operation to keep injector duty cycle under 90% and that was our goal. This plot shows 64% Injector duty to achieve the same power. Flowing the same amount of fuel with the injector being on only 64% of the cycle.

Our goal was to make more power and to do that turn the boost up higher than the 15-16psi range. Bigger injectors are obviously the smartest, safest, most efficient way of doing this. Injectors must be tuned for by a experienced tuner to achieve proper results and deliver the correct amount of fuel at the correct time. Bigger injectors does not mean dumping more fuel all the time, they are just able to flow more fuel when desired.

With the bigger injectors, we were able to produce 11 more peak whp while dropping injector duty cycle over 30% producing a much safer operation. This was at 18psi of boost and a perfectly stable AFR on 93 octane fuel.

Fuel is horsepower, no way around that fact. Doing everything to produce more airflow with it being an intake or exhaust is nothing without the proper air to fuel ratio. Consider doing the right thing and following the correct upgrade path to allow for more power safely.

| Item | Price | Qty | Total | |

|---|---|---|---|---|

| Subtotal |

$0.00 |

|||

| Shipping | ||||

| Total | ||||

Comments

Leave a comment